When I explain textile techniques, one of the basic things that come up again and again is weaving - especially the topic of warp-weighted looms. Explaining the natural and artificial shed, and how weaving is done on that loom type, is easier done as demonstration, but obviously there's not always a loom available.

So, when in the situation of having to explain this stuff ages ago for a seminar, I cobbled together a small functional model of a warp-weighted loom. The "cloth" that I set up for it, though, was very narrow, and the heddles were not well done, and the weights were... well, let's say "cobbled together" does really just do it justice.

Now there's another explaining occasion coming up on the horizon (well, actually, on the pretty close horizon), and I decided to set the loom up again, properly this time. Which means actually doing a bit of maths to figure out a sensible loom weight weight (does that make sense?) and thinking about scale a little.

Scaling down textile stuff... it's a pain in the neck. One of the basic problems of scaling down things for models is getting the textures right. If we're thinking textiles and especially garments, this includes fall and drape of the things - and that typically means yo need to use a much finer, thinner material than the original is made of.

This can be possible in some instances, but when you have a fine, drapey fabric from the start, you'll run into the nigh-impossible very soon. This, by the way, is the main reason why I have never done garment reconstructions on a smaller scale than human-sized, and why I am not a fan of showing clothing (reconstructions) on dolls. It just won't work with the original material, and scaling down small stitches and seams is another can of worms I'd rather not open.

Another scaling-down problem is the size-to-weight ratios of things. Obviously, for a for-show-only thing, this is not relevant - but if you want a functioning model for demonstration purposes, it will bite your behind quicker than you can say "volume". If you take a cube with 2 cm side length, its volume is 8 cm³. Double its side length to 4 cm, and it will have 64 cm³ volume. Now if you want to scale down a warp-weighted loom and wish it still to function, you need a minimum tension for each thread, and you'll have more threads per cm on your loom than in the original fabric, so you will need more tension per cm - and you have less space for loom weights if they are supposed to look roughly in scale. Which means... you need a material with higher density than the original.

For the first instance of the loom, I just used wooden globes with a bore through the middle, giving just enough weight for the shed to open (albeit a little unwillingly). That does not look good, though, nor does it work really well, and especially won't really work for a wider weave.

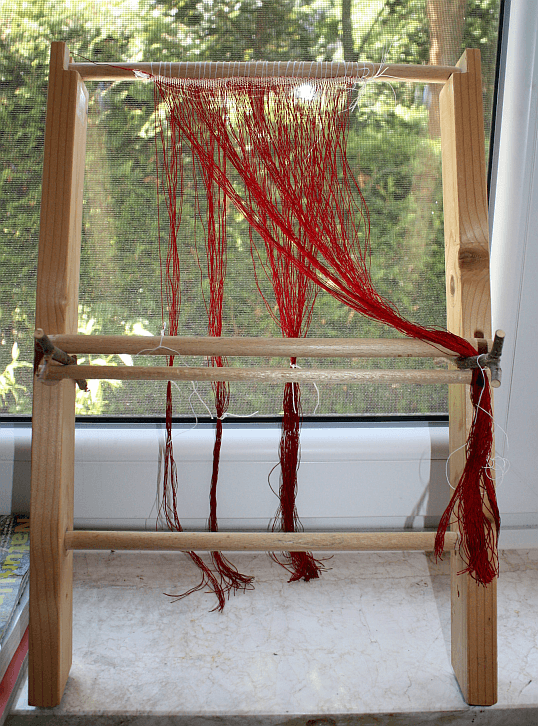

Since I want to get sensible tension on the threads, though, I might find myself in a fishing tackle store later today, to buy lead weighs originally intended to lure carp to their doom. And then I can move on to get this loom set up - because right now, it looks like this:

...and that's a little unfinished, and a little sad. Also, I'd like to have it working properly on Monday... what was that quip about the last minute being so important, or else nothing would ever be finished?