Yesterday somehow was one of those slow, feels-like-nothing-gets-done days, so I sat down in the sun to do some spinning. And what can I say, other than my spinner-self showed my scientist-self that the latter had totally underestimated the power of the spindle stick when designing the spinning experiment... but let me explain.

For the Hallstatt project, I am spinning a thread thickness that does lie below my normal don't-think-about-it, do-it-in-your-sleep thickness. It is thin enough to mean that I need to pluck out or stretch out even micro-slubs to get a smooth, good-quality thread. It's always very hard to give difficulty ratings to thread, but it is definitely not the most undemanding spin.

My favourite spindle is one that I have been using for quite a while, since before I got the spindle-stick replicas made. That means the stick is home-made, from an old cedar wood arrow, and that means it is whittled down on top and bottom, but not to a very pointy point - more like a token rounding off on top especially. (Whittling is not my forte, and I much prefer spending my time doing something I can do well.) And since I don't usually spin for production, but mostly for demonstration, I usually leave the stick in and just slide off a finished cop of wool (most often to stuff it somewhere and forget about it for a while). But I have used the whorl with the Bergen sticks too, and they generally do work for me - I'm just not using them normally.

When I went to the Wooly Week Workshop, I brought my spindle whorl, a few of the Bergen sticks, and the cedar stick (with the whorl on that). And when we started, I used the cedar stick because, well, it was already in there and handy, and I use it all the time when I demo. So I did get "spun in", if you want to say so, with the spindle on the cedar stick, which I used all week for the tests.

Fast forward to the "production phase" here. Since one of the benefits of a removable whorl is that you are able to just swap sticks and ply off the two spun-full sticks later on, I thought I'd just continue with one of the Bergen sticks. And that is where I was thwarted yesterday. I tried spinning with the Bergen stick - and the spindle runs very well, very fast with it; there is little wobble because the tip is tapering so nicely; it feels good... but I was not able to spin the correct gauge thread with it, and I got breaking thread way, way too often. Believe me, I really tried hard to spin with it, but it just would not work. Finally I switched back to my thick-tipped cedar stick, and it worked much, much better again. So what happened? What is the difference between the sticks?

Is it added weight? The Bergen stick is a bit heavier than the Cedar stick, but that is not what brought me down - during the Wooly Week, I usually had a good-sized amount of thick starter thread wound around my spindle, bringing it up to a significantly higher weight than yesterday's assembly with Bergen.

Is it changed MI? According to André Verhecken, who does research about MI in spindle whorls, the stick does not change much - and a difference of one or two grams will not change anything significant in the MI.

But something changed when I changed sticks - something significant enough to keep me from making the thread I wanted to make. And as I watched myself spinning, I found out what else had changed - the stick diameter close to the top, where I put my fingers to give spin to the spindle. Bergen tapers very slowly from an already slim shank to a slim point about 3 mm wide, while Cedar is much thicker, probably about 6 mm in diameter where I place my fingers, and tapers over a short distance only. And I got the impression that when I give twist to the thinner shank, the spindle will turn a lot faster than when I give twist to the thicker shank... which would be a considerable influence on my spinning, and which would explain why I was getting more breakage - too much spin on the thin thread.

That means that, given time and practice, I could most probably adapt to the faster-spinning spindle setup and change over to the Bergen sticks, either giving less (slower) spin to the stick or drafting faster; though for these fine, finicky threads, drafting faster is not really an option.

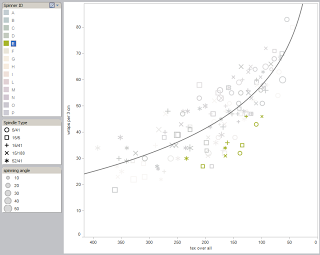

And it means that, because I was not aware of how much spindle stick shape can influence spinning, the stick was a variable totally left out of the experiment 2009. On the other hand, adding yet another variable to check would have been too much for one week of testing time, and of course all spindle sticks on the experiment spindles were the same - so it's possible to develop a follow-up experiment with modified spindle sticks and then continue researching into this topic with all the data we have.

And this means that my scientist-self will think about spindle sticks, and experiments, and how it could be tested, and all kinds of things like that during the hours I will spend spinning the Hallstatt threads... after I whittled myself another chunky cedar stick, that is. Because that will take a lot less time and effort for me than to learn now how to cope for the higher spin on Bergen for the Hallstatt threads. Because after all, my spinner-self is still just a lazy spinner.