Search the Blog

Latest Comments

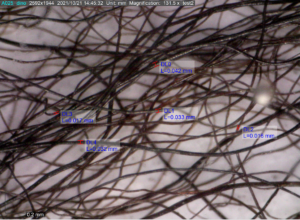

Fibre Thickness Measurements.

Anyway, here's a picture for you so you can see how that looks:

This is the fibre I'm using for the corded skirt, the cord part. I suspect that the measurements I took are a little bit high, because I have another kind of fibre where I know the micron count, and my measurements were consistently higher than the count that was listed... so, well, probably needs some more practice, and some calibrating of my own eye, and possibly I need to move that one pixel inside instead of outside.

Also... taking these measurements is quite time-consuming! Especially regarding the fact that you need to take measurements from about 100 fibres, randomly selected, to get something like a proper histogram of the fleece (or fleece part) that you are looking at. I only took a random sample of some few fibres, and I probably won't go for the 100 for now. There's other things to do that are more important right now (and I know already that the fibre profile of the stuff I can get does not match the Bronze Age sheep...)

Comments 2

I can't help but wonder how much you can automate the process? Geologists regularly let software automatically identify mineral grains, determine the locations of borders between different minerals , and the report the percentage of each mineral in a microscopic image. It needs checking to be certain that one correctly defined the visual parameters of each mineral, but checking is way faster than circling each mineral grain by hand and then calculating their area.

I guess to get the thickness of the fiber you'd need a program that chooses a random location, determines if it is fiber (dark) or background (light), then, if fiber, checks all of the adjecent pixels to see if they are still fiber, and then progress outwards from the starting point in all directions till it encounters pixels in the background colour. Once the boundaries of that fiber are thus determined then it can measure the shortest distance between one edge and another to determine the thickness of that point. Repeat 100 times. Or 1000. The computer doesn't mind doing repetitive tasks.