Sorry for the blog silence yesterday - I got so caught up in textile work that about everything else on my "to do daily" list slipped past me, including (obviously) doing a blog post. It was a very successful day otherwise, though. I have progressed from the "pure testing" stage into the stage where testing segues into actual work; so yesterday, I made two warps.

The current museum project is the reproduction of Bronze Age garments for a museum, to be used in hands-on sessions for visitors. I've posted about

the wool problem before (there's no sheep left with the appropriate mix of fibres), so I'm using compromise wools. The rest of the project, though, I'm of course aiming to get as close to the originals as possible, so the people handling the items will get the best experience, and impression, possible.

This means spinning to the same thickness and twist angle as the originals - which is not quite as easy as it sounds, because, well, there's aiming to do something just so and managing to do it just so, and those two don't necessarily coincide. Also, if a yarn looks right when your are spinning it does not always mean it will look right once it's been soaked and stretched and dried again, or when it has been made into a warp. Things can happen on the way... and then you will have to adjust.

Trying to get as close as possible also means weaving, or plying, or twisting tests. There's been one test warp for the Egtved belt a while ago, where I found out that my yarns were a bit too thin; now there's a second warp strung up in the living room, and this time, it looks much better.

I'm working with 1:1 scale printouts of the finds to check if what I'm doing is the right size, and shape, and density. The feeling when you hold your piece next to the print, and it matches? That's so, so satisfactory.

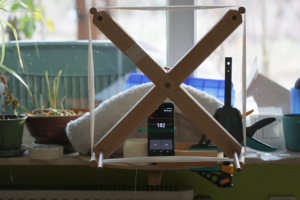

This is the first of the warps I set up, the one of the belt; the other one is for the corded skirt, and that setup was, so far, also successful. The skirt band consists of several sections, the first of them without the extra selvedge cord for the corded part, and with a plied weft, just plain woven - and I have already finished that part. It looks very unspectacular:

You can already see the thick selvedge cord anchored in the weave, and coming out on the right side. Next section will be the part with the cords!

Getting there! There's a little bit of fibre sticking out of the wrap, but overall it looks good to my eyes.

Getting there! There's a little bit of fibre sticking out of the wrap, but overall it looks good to my eyes.