So, here we are - de-gumming results:

The procedure I did yesterday resulted in colour loss and definitely loss of some, but not all sericin - the silk still has a rather firm hand and is stiffer than I'd expect it to be if completely de-gummed.

You can see the narrow band of lighter silk on the gummy original silk, and the completely de-gummed and then dyed silk on the left side. Maybe I should take another small sample of the gummy silk and try to get all the gum out by boiling it within an inch of its life? See what happens then?

In other news, I've been busy in the background working on the website re-launch. As usual, it eats up all the time it can and then some, and there's other things to take care of and work on (such as the Egtved Project, for which you're also due an update), too, so it's actually feeling a little like a wonder that I have made as much progress as I have. The learning curve is also rather steep - in the past few days, I've successfully dabbled in CSS, altered php scripts (do not leave an extra . in or you will get a lovely error), edited sql tables by adding columns, written an sql update thingummy to replace values in a column (it's called Abfrage in German and I don't know the English term), and used a regular expression for a search-and-replace routine. I've also cursed the inconsistency of things when an installation went wrong and pondered the pros and cons of starting over or not. (Verdict? I'll try, and if it goes wrong, I'll go with the semi-clean install that seems to work okay for now.) At least I cannot complain about lack of challenges in all kinds of fields!

The procedure I did yesterday resulted in colour loss and definitely loss of some, but not all sericin - the silk still has a rather firm hand and is stiffer than I'd expect it to be if completely de-gummed.

You can see the narrow band of lighter silk on the gummy original silk, and the completely de-gummed and then dyed silk on the left side. Maybe I should take another small sample of the gummy silk and try to get all the gum out by boiling it within an inch of its life? See what happens then?

In other news, I've been busy in the background working on the website re-launch. As usual, it eats up all the time it can and then some, and there's other things to take care of and work on (such as the Egtved Project, for which you're also due an update), too, so it's actually feeling a little like a wonder that I have made as much progress as I have. The learning curve is also rather steep - in the past few days, I've successfully dabbled in CSS, altered php scripts (do not leave an extra . in or you will get a lovely error), edited sql tables by adding columns, written an sql update thingummy to replace values in a column (it's called Abfrage in German and I don't know the English term), and used a regular expression for a search-and-replace routine. I've also cursed the inconsistency of things when an installation went wrong and pondered the pros and cons of starting over or not. (Verdict? I'll try, and if it goes wrong, I'll go with the semi-clean install that seems to work okay for now.) At least I cannot complain about lack of challenges in all kinds of fields!

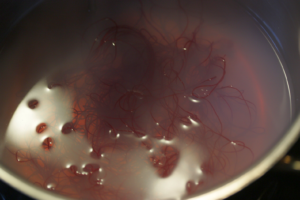

During the de-gumming process - it's starting to lose some of the colour to the soap soup.

During the de-gumming process - it's starting to lose some of the colour to the soap soup.