Yesterday's Praise of the Distaff raised two questions in the comments that I'll address here, since answering them will take some linking as well.

Chris asks:

"I was always told that if you saw someone spinning with a distaff in a medieval picture, it meant they were spinning flax. Is there documentation of a distaff being used with wool?"

I've been told that, read that, or heard that as well, and I think it might stem from the fact that when you are spinning on a wheel, you can place the wool fibre in your lap, thus saving the distaff. However, flax fibres in a lap will very soon end up in a huge knot - they are too long and too tangle-prone to spin without help of a distaff, even on a spinning wheel. This leads to a "wheel-based" strong connection in modern spinner's minds, which is basically Distaff=Flax, and Wool=No Distaff. However, I have yet to find a medieval picture of a spinner not using a distaff - they all have one.

Yet you can tell whether somebody is having wool or flax on the distaff - because the shape is different. If the loaded distaff looks like a stick with a traffic cone on, it is long fibre - probably flax; if it looks like candy floss (candy cotton for you US folks), it's short fibre - probably wool. And that brings us directly to the next question, which comes from Panth:

Is there any chance you could do a photo-tutorial of how you load your distaff with wool, particularly with how to load it with wool rolag(s?) prepared with hand cards (if, indeed, that's applicable). I have both distaff and drop spindle and would dearly love to make the leap towards more historical hand spinning but have been having trouble with loading the distaff effectively.

Well, I could, but it would probably take me ages, so I'll do the lazy thing and link you some stuff already on the internet.

There is a photo tutorial (in German, sorry) showing and explaining how to load a distaff with flax (the long-fibred stuff, not the short waste bits you buy as top nowadays) done

by Faserfieber. For those of you not reading German, basically you open up the skein (Flachszopf), shake out the dust, loosen it up by laying out the fibres in thin layers, one on top of the other, on your lap (this gives you a fibre triangle in your lap), and then carefully roll it around the distaff. You fix it with bands on top and additionally close to the bottom; the bottom band is removed for spinning.

This gives you the characteristic traffic cone shape with the also characteristic bands around it. You don't use these bands for wool, so whenever you see a distaff in cone-form with bands, it's flax (or hemp, or nettle - but one of the long plant fibres).

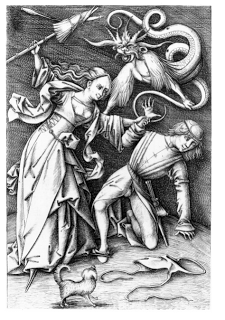

So she's spinning flax:

(when she's not beating up her husband with her distaff, that is)

while this girl here

looks more like a wool-spinner to me. No proper cone-shape on the distaff there - and I'd suspect the two parallel diagonals across the fibre blob are meant to hint at the wool roving wound around the distaff. And yesterday's peasant lady is also definitely spinning wool, by the shape of the fibre on her distaff.

I haven't been able to find a photo tutorial about how to wrap wool around a distaff, but I can tell you: You don't need one. If you are preparing your fibre yourself, you want to get a long enough sliver of roving from it. That is easy if you comb your fibre - just diz it off. I haven't tried this myself, but I think you could do the following with hand-cards: card an amount of wool, maybe three or four carding portions; do not make them into rolags, but place them into a stack and then pre-draft them through something with a suitably small hole in it to get the right shape.

If you are not preparing your fibre yourself, get a nice long (at least 80 cm long) strip of batt or stretch out a bit of commercial top so that it's not as chunky.

In any case, you should now have a strip of prepared, pre-drafted fibre. Now you grab a stick that is between 45 and 120 cm long, according to your preference. Any stick will do, as long as it's not too smooth, you want it to have some "grip" on the fibre - and now wind your length of fibre around the stick, just like you would wind thread on a bobbin. That's it.

I hope that helps!