A while ago, I got a commission for a gold and silk band, woven on the rigid heddle. Which delighted me no end, since I just love working with these materials, and I love rigid heddle band weaving, and the band itself is totally stunning in its simplicity. So I did the calculations, and the test run, and everything looked A-OK. Green. All systems go.

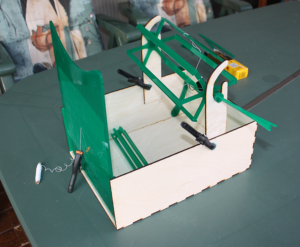

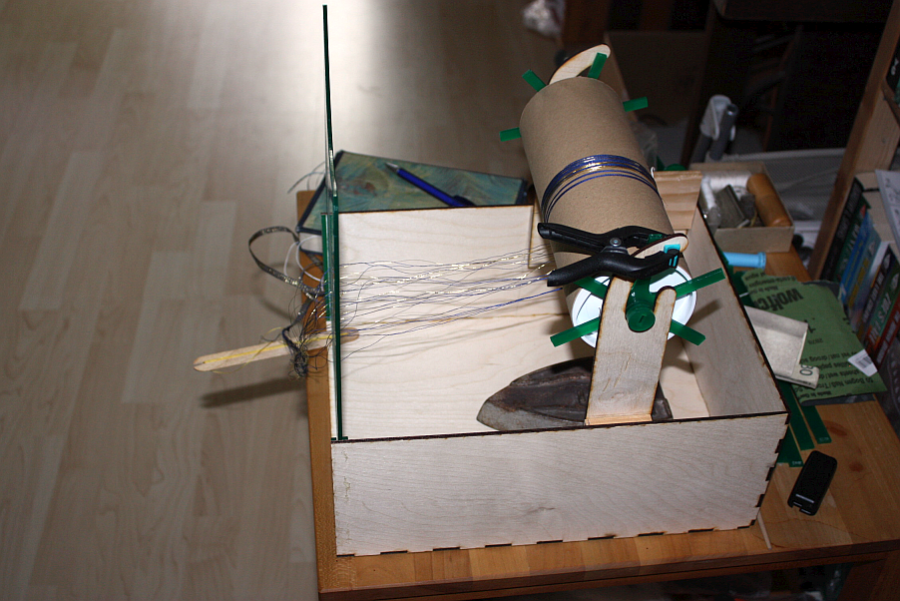

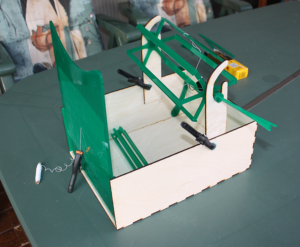

I even made a boxloom for this, to have something to wind up the long warp, so everything would stay balanced and nice and tidy. You might remember this:

Well. It then evolved a bit (which was to expect)...

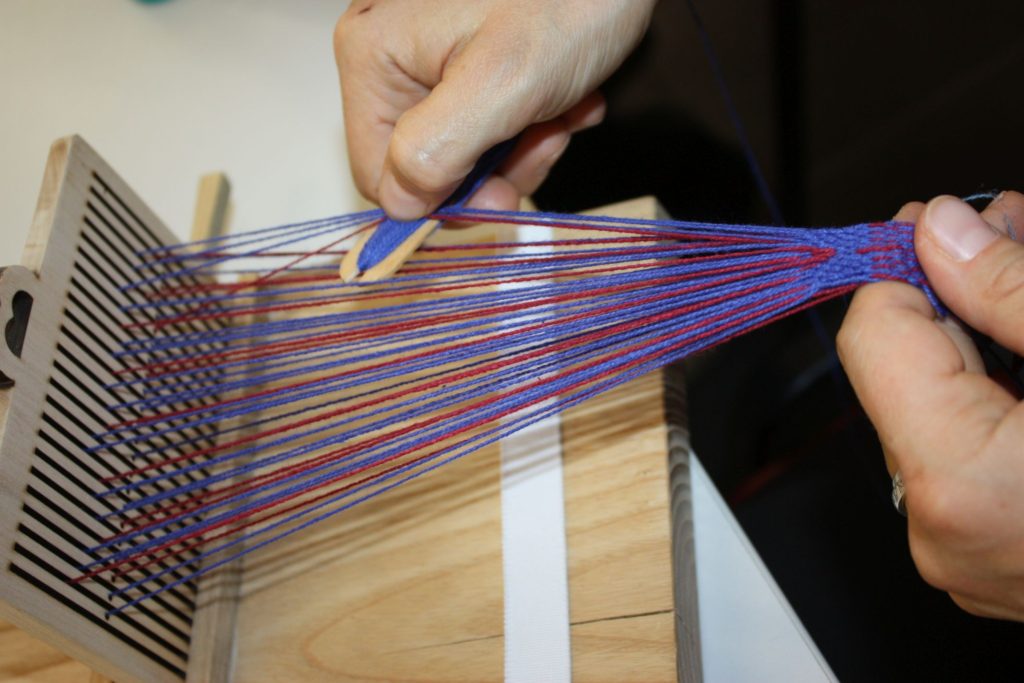

...and for the final run, because the laser had not cut all the slits perfectly and some had a rough spot, I decided to use a wooden rigid heddle (way too wide, but who minds, right?) instead.

The warp was warped, the ends were threaded through the heddle, weaving started... and I quickly discovered that while my calculations for the bandwidth were correct and I had plenty of warp (I'd made it a bit longer, just in case), there were problems.

Tension problems.

The threads, both gold and silk, are fine and smooth and slippery. This can cause an issue when not holding the band at the very same angle to the heddle all the time, because then it will curve (or zig-zag). This is not as obvious with the narrower test bands I did, but with 1.5 cm of width to weave? It suddenly becomes an issue.

The threads are also very, very different from each other regarding their elasticity - which means that though the warp was nicely tensioned at first, it very, very quickly deteriorated.

Well. Tools evolve, right? And when something like this comes up, you cope with it as best you can. Which, in my case, meant... unboxing.

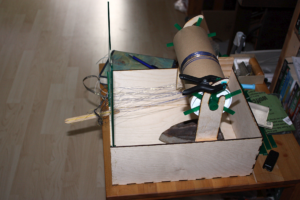

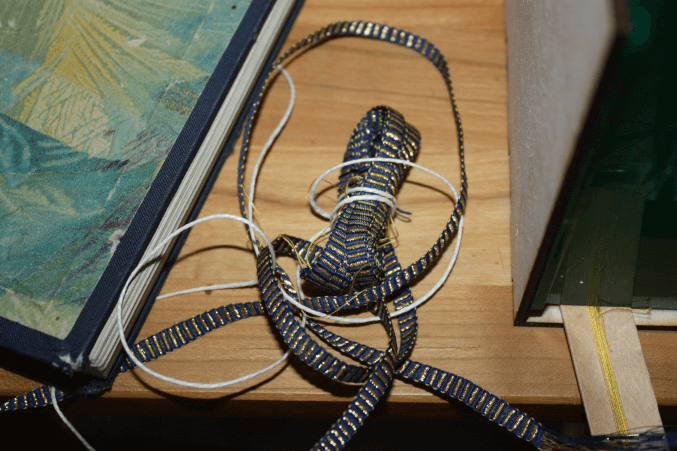

See what I mean here:

There's a white cord temporarily taking my place, holding the woven end of the band (hooray for foldback clips). There's a red cord tensioning the main warp, through the whole room - twice, actually. This is how it looks from the other side:

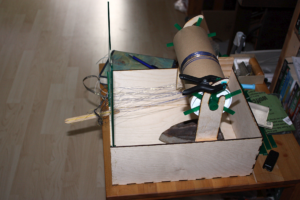

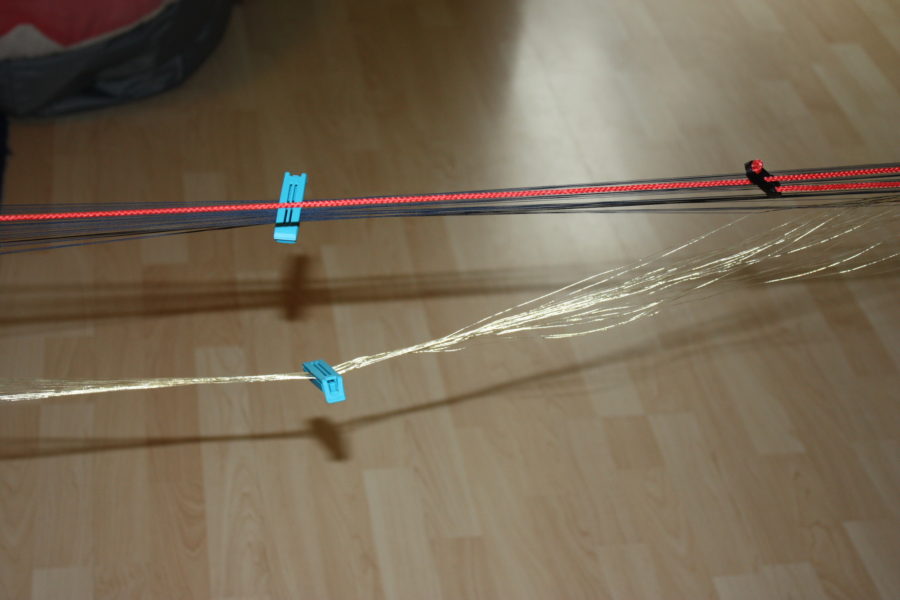

Because it is easier to adjust the tension a smaller bit of warp at a time, there's clamps a bit behind the heddle:

...and you can see here, in the picture taken before I installed the final thingummygadget (made from a piece of string), that the difference in warp tension is really huge, only a relatively little way into the weaving process.

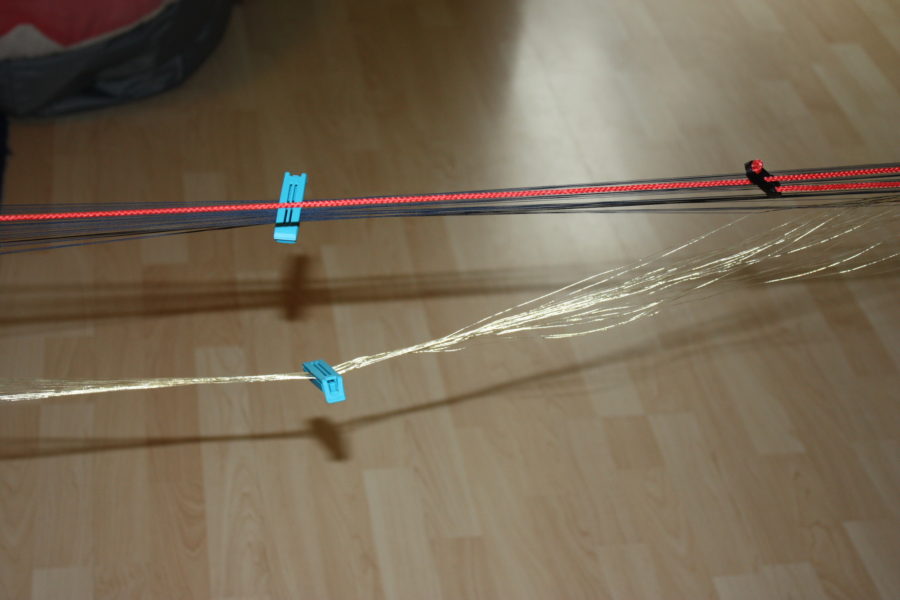

So here's the coup de grace for this issue:

Silk and gold warp separated, then tied together with a bit of string, and that is used to tension them. Voilà - equal tension for the two.

Next time I'll make something like this from silk and gold? I'll handle things a good bit differently from the very beginning!