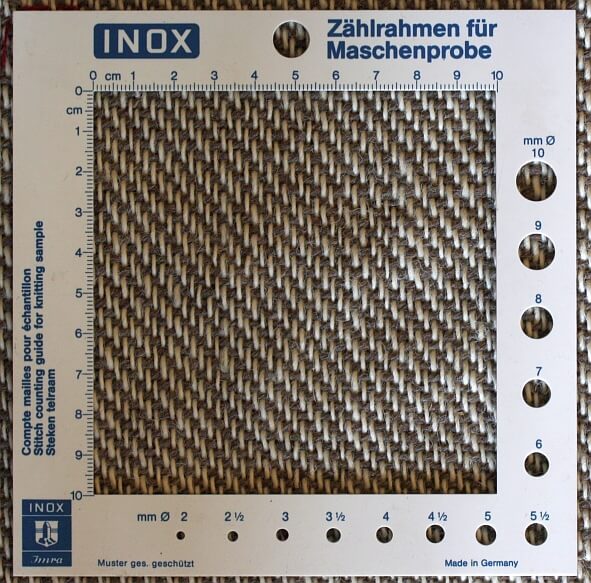

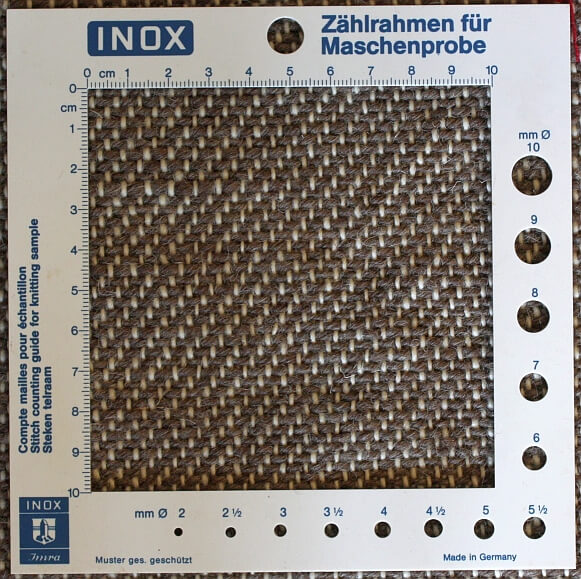

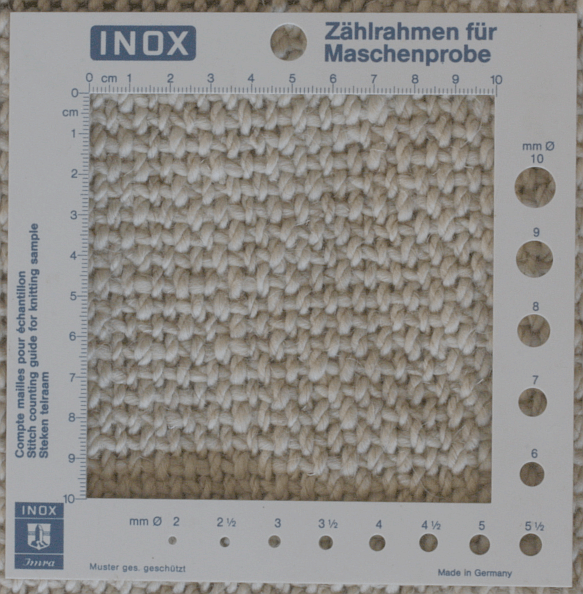

I've taken a few closeup photos of the sailcloth after washing, and, well, have a look for yourself:

Now... it looks to me as if the twist angle of the white yarn is about the same or seems to be even slightly lower than it was when spinning (I have the reference cards to compare with), but the brown weft yarn now clearly looks higher-twist than what I spun (which was about 30° approximately). This is definitely... interesting.

Next step for the cloth will be getting fulled, and I'll take another closeup photo then and give it another reading. But my first conclusion from all this looking at twists and getting stuff woven and comparing is: Twist angles lie. Do not trust that they are spun like what they appear to be in a finished cloth - and in further conclusion: If you need to do a hair-splittingly exact replica of a piece of fabric, you will have to do test-spinning and test-weaving and look at the angles in the finished fabric to figure out what you will have to spin.

Good thing I'm already mildly crazy, or that would drive me towards craziness indeed. Can't that textile stuff be straightforward once, just for a change? Please?

Now... it looks to me as if the twist angle of the white yarn is about the same or seems to be even slightly lower than it was when spinning (I have the reference cards to compare with), but the brown weft yarn now clearly looks higher-twist than what I spun (which was about 30° approximately). This is definitely... interesting.

Next step for the cloth will be getting fulled, and I'll take another closeup photo then and give it another reading. But my first conclusion from all this looking at twists and getting stuff woven and comparing is: Twist angles lie. Do not trust that they are spun like what they appear to be in a finished cloth - and in further conclusion: If you need to do a hair-splittingly exact replica of a piece of fabric, you will have to do test-spinning and test-weaving and look at the angles in the finished fabric to figure out what you will have to spin.

Good thing I'm already mildly crazy, or that would drive me towards craziness indeed. Can't that textile stuff be straightforward once, just for a change? Please?