Back in 2012, we already did a dyeing experiment at the Forum, investigating the influence of kettle materials on the colour outcome. Our outcome showed a significant difference between the kettle materials that we tested - which were lead, copper, and iron. The results of this experiment were published in EXARC journal (you can read the article here).

In 2013, I was able to do an add-on to this original experiment, investigating whether the influence was larger in the mordanting or in the dyeing process. Sadly, I omitted the reference (NEVER leave out the reference!!) so there was no way to compare the original experiment and the add-on with each other. (Any comparison would have been limited anyways, as they were two different runs with different batches of birch leaf - but having two references to compare would have given good information about the similarity of the dye batches. Well.)

And ever since 2012 and the original experiment was done, I've been looking for somebody who would like to repeat the experiment... but nobody took the bait.

So this year at the Forum, we did the repetition ourselves. We did the full run this time around, though, combining the original experiment (metal in both the mordant and the dye) with the add-on (metal only in the mordant, or only in the dye). This caused some serious brain-bending and thought-knotting in the preparation as I was trying to make the run as efficient and as sensible as possible while avoiding any contamination between the skeins and any other issues.

There were two reasons for this re-run: One, to see how the three different batches (metal in mordant only, in dye only, in both) compare to each other. Two, to finally have an archaeological experiment repeated (something that, to my knowledge, has never happened before).

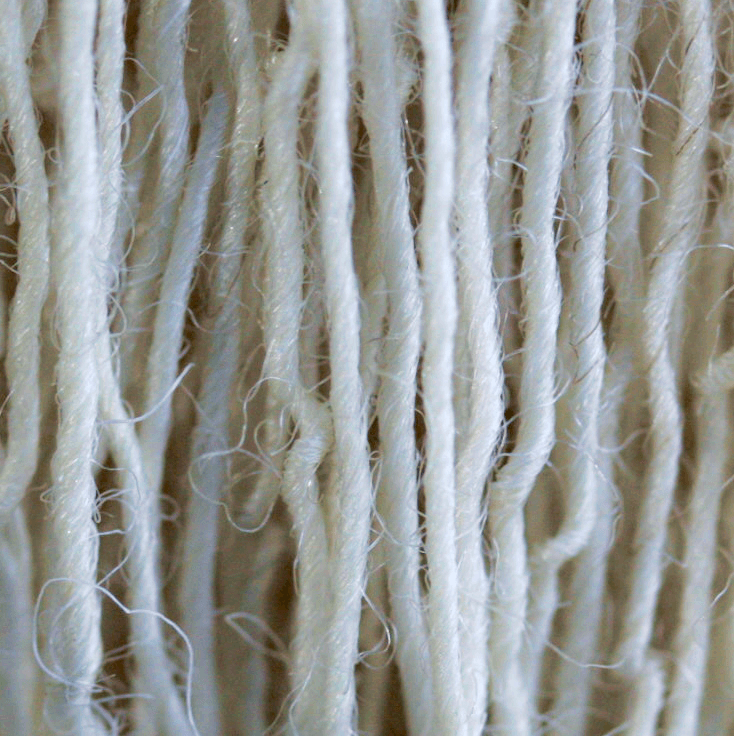

So things happened. Skeins were wound...

...and mordanted...

... dye liquid was boiled, and filtered off...

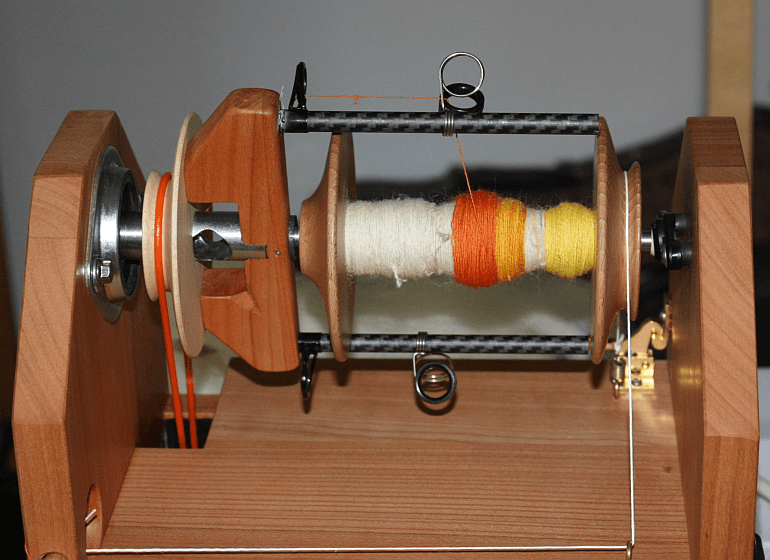

...and split up between fourteen pots.

Then, skeins were dyed (that was a long night!).

They were rinsed, and labelled, and dried.

And, of course, they were discussed!

So, the outcome?

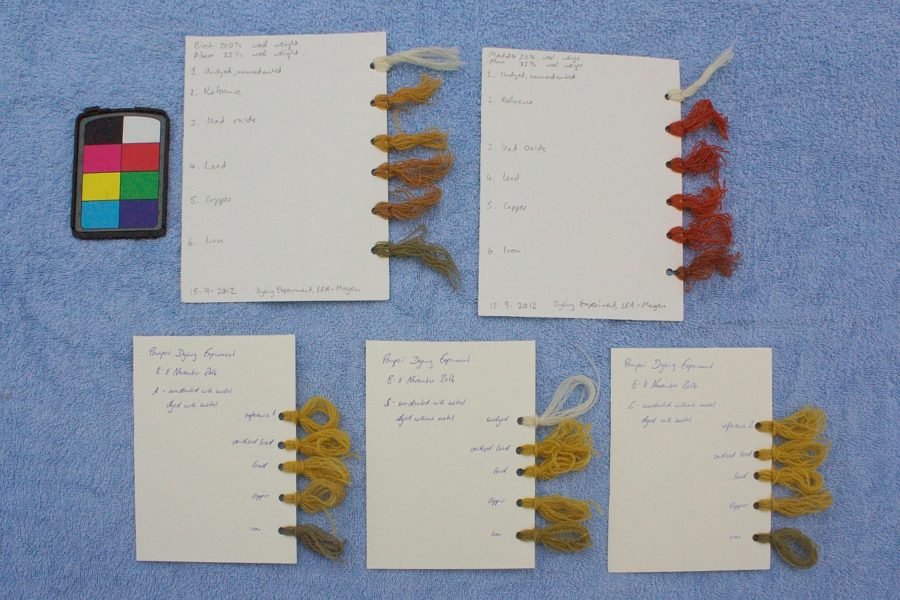

Our experiment was successfull on both counts. One, it does show that there is a more pronounced influence of the kettle wall when dyeing than when mordanting, and that it adds up when the metal is present in both. Two, that it is really important to repeat archaeological experiments, because the natural stuff that is part of almost all of them can result in weird outcomes, or in huge differences.

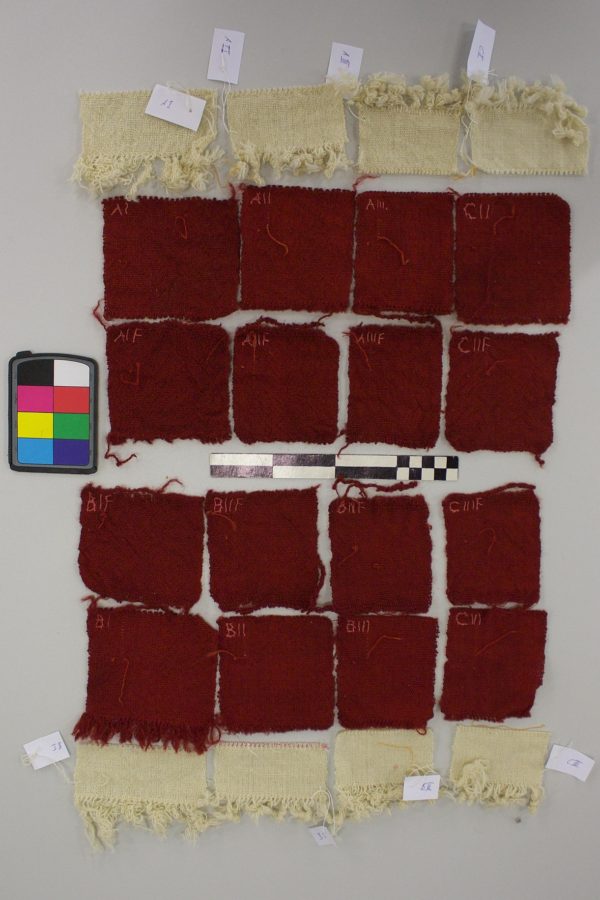

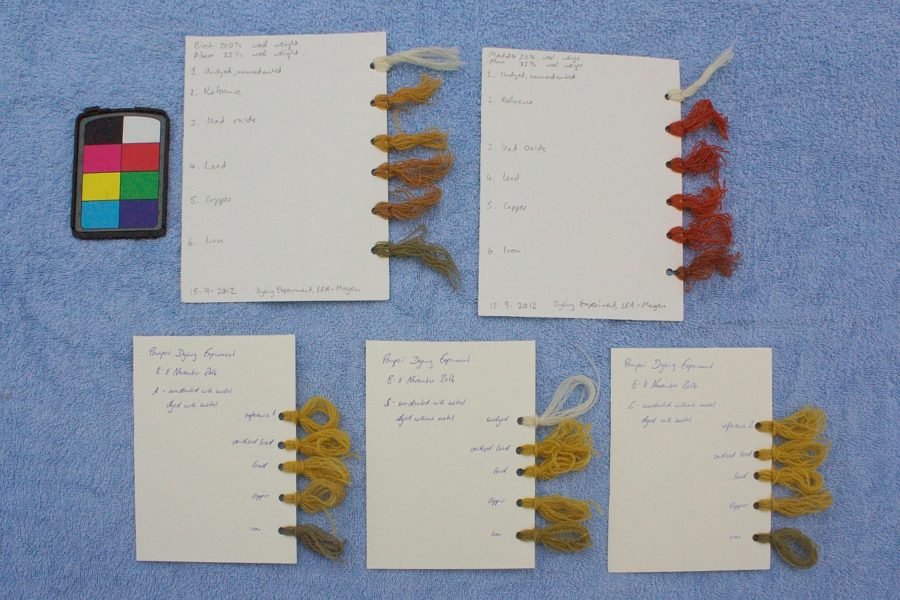

You can see the differences here - top left is the original experiment result in birch (top right was a madder dye run). On the bottom left, metal was present while mordanting and dyeing; bottom middle, metal only when mordanting; bottom right, metal only when dyeing.

Time well spent, I'd say.

In 2013, I was able to do an add-on to this original experiment, investigating whether the influence was larger in the mordanting or in the dyeing process. Sadly, I omitted the reference (NEVER leave out the reference!!) so there was no way to compare the original experiment and the add-on with each other. (Any comparison would have been limited anyways, as they were two different runs with different batches of birch leaf - but having two references to compare would have given good information about the similarity of the dye batches. Well.)

And ever since 2012 and the original experiment was done, I've been looking for somebody who would like to repeat the experiment... but nobody took the bait.

So this year at the Forum, we did the repetition ourselves. We did the full run this time around, though, combining the original experiment (metal in both the mordant and the dye) with the add-on (metal only in the mordant, or only in the dye). This caused some serious brain-bending and thought-knotting in the preparation as I was trying to make the run as efficient and as sensible as possible while avoiding any contamination between the skeins and any other issues.

There were two reasons for this re-run: One, to see how the three different batches (metal in mordant only, in dye only, in both) compare to each other. Two, to finally have an archaeological experiment repeated (something that, to my knowledge, has never happened before).

So things happened. Skeins were wound...

...and mordanted...

... dye liquid was boiled, and filtered off...

...and split up between fourteen pots.

Then, skeins were dyed (that was a long night!).

They were rinsed, and labelled, and dried.

And, of course, they were discussed!

So, the outcome?

Our experiment was successfull on both counts. One, it does show that there is a more pronounced influence of the kettle wall when dyeing than when mordanting, and that it adds up when the metal is present in both. Two, that it is really important to repeat archaeological experiments, because the natural stuff that is part of almost all of them can result in weird outcomes, or in huge differences.

You can see the differences here - top left is the original experiment result in birch (top right was a madder dye run). On the bottom left, metal was present while mordanting and dyeing; bottom middle, metal only when mordanting; bottom right, metal only when dyeing.

Time well spent, I'd say.